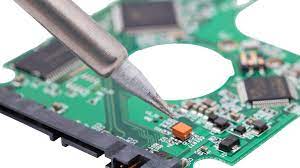

Components Solded onto an Assembled Circuit Board

The process of soldering is used to join electrical components together, creating a strong and durable connection that can be easily re-heated (desoldered) if necessary. It’s an essential skill for anyone who wants to build assembled circuit board, and it’s not too difficult to learn with a little practice. The most important thing to remember when soldering is to use a low temperature for the joint. High temperatures can cause the metals to melt and flow over each other, creating a weak bond that’s less likely to hold up under strain.

To get started, make sure that your soldering iron is clean and ready for use. Then, position the tip of the iron over both the PCB copper pad and the component lead you’re trying to connect. The solder will heat up as it comes into contact with the two materials and will begin to flow into the hole in which it is inserted. As it cools, the solder will create a solid bond that connects the leads and forms an electrically conductive joint.

Once the solder has cooled, it’s time to cut off any excess. A sharp wire cutter is a good choice, since it will give you a straight, flat cut and minimize the risk of creating a short. Then, you can move on to the next step in the assembly process.

Depending on the type of circuit board being assembled, it may be built using one of two technologies: surface-mount or thru-hole. SMT technology is the more common, and it’s used to build all the electronic devices you see in your home and in businesses around the world.

How Are Components Solded onto an Assembled Circuit Board?

In this method of assembly, a thin layer of solder paste is applied to the PCB. Assemblers apply the paste using a stencil, which is similar to screen-printing a shirt. The stencil outlines the areas where assemblers should put the solder.

Assemblers then pick and place component parts on the PCB with a machine called a pick-and-place robot. They do this by referencing a set of manufacturing files known as Gerber data. These files contain all the information needed to manufacture the circuit board. They also include a list of parts that should be populated on the board and a list of parts that should not be populated on the board.

The populated circuit board is then placed in a reflow oven, which will heat the solder paste and help it flow into the holes where the components are being attached. As the solder flows, it will bond with the copper traces and the component leads. This forms a strong and reliable joint that’s capable of surviving the vibrations and shocks that occur during the assembly, testing, and shipping of electronic products.

The other major method of assembly is thru-hole, which involves drilling holes into the PCB through which electronic components can be pushed. The components’ leads are then inserted and soldered to the board using a selective soldering machine. As with SMT, a quality inspection is conducted before and after the process.